Why Cataphoresis?

- Home

- /

- Why Cataphoresis?

WHY DO WE COAT SUNFLEX BRACKETS WITH CATAPHORESIS?

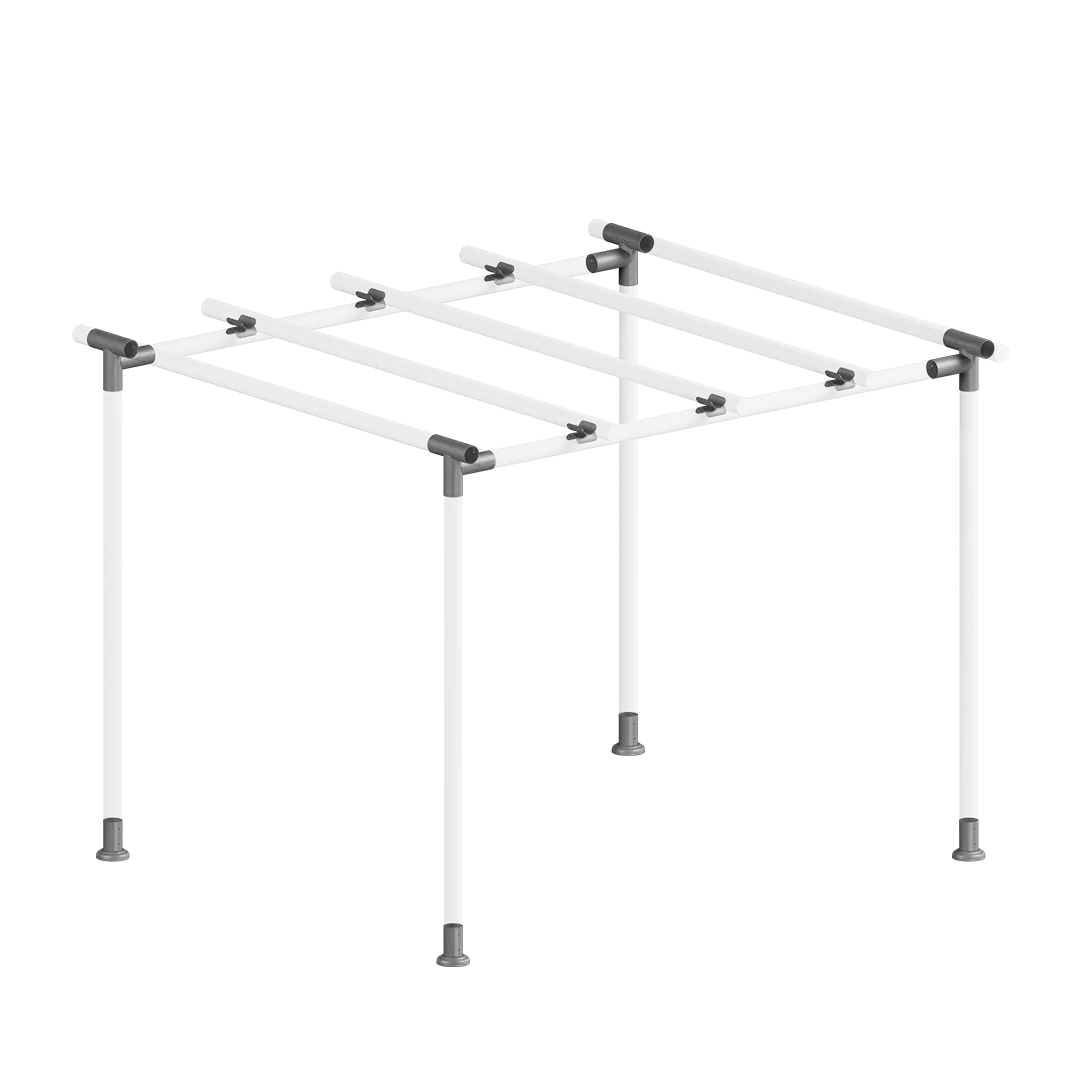

Wooden Pergolas that you will use in your garden or terrace become a part of your home. After setting aside your labor and savings for pergolas to be used by the sea or in different climates in summer and winter, corrosion after a short time can cause unhappiness and require repainting or repair. It is almost impossible to repaint brackets in installed Pergolas.

In products made of Galvanized Profile or sheet metal, which is an alternative, the galvanization of the cut, drilled and welded surfaces disappears and the product corrodes from these processed places and rusts in a short time.

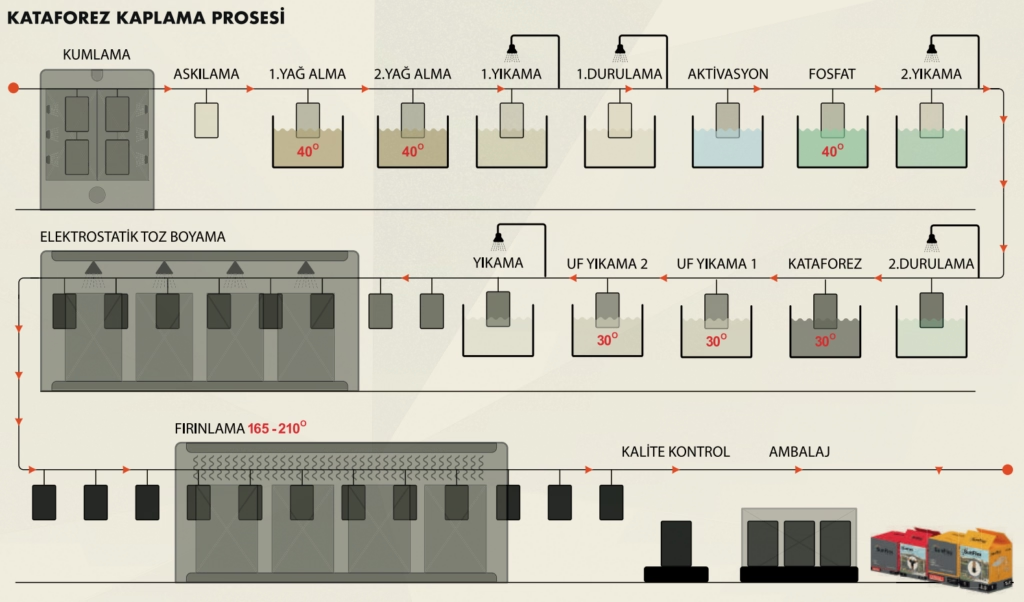

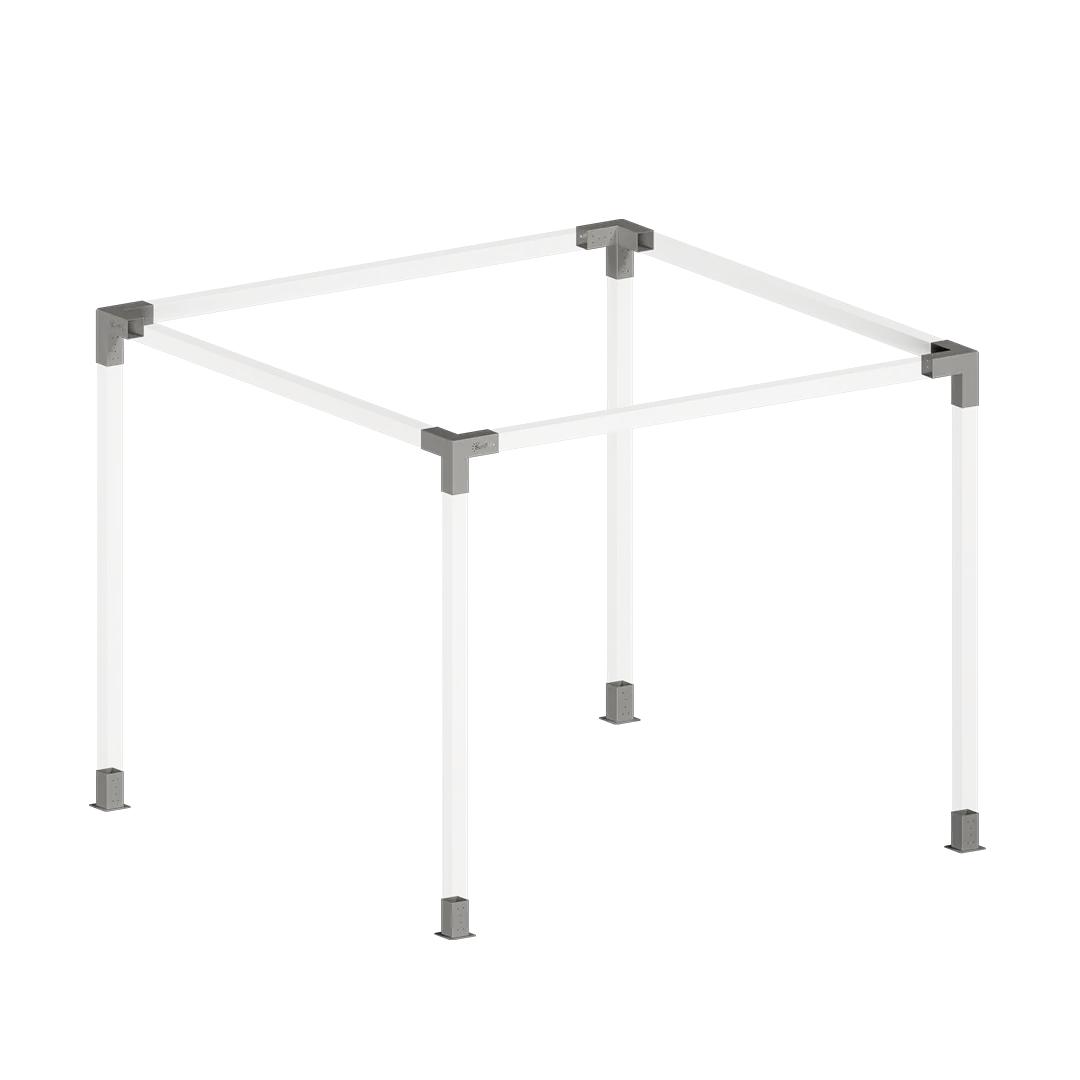

Sunflex Brackets are coated with immersion cataphoresis on sandblasting before painting after cutting, hole welding processes are finished, and then painted with electrostatic paint. With this process, it has a minimum warranty of 10 years barring impact damage. You will be able to use Sunflex Brackets for much longer periods.

Cataphoresis coating is an electro coating process based on electro chemistry principles. It is a very effective method for protecting complex geometric metal parts showing conductive properties from corrosion by painting. Cataphoresis technology is environmentally friendly. Cataphoresis is used as under-paint corrosion protection coating for chassis and visible surfaces of cars, buses and trucks.