Bracket Production Process

- Home

- /

- Bracket Production Process

SUNFLEX BRACKET PRODUCTION PROCESS

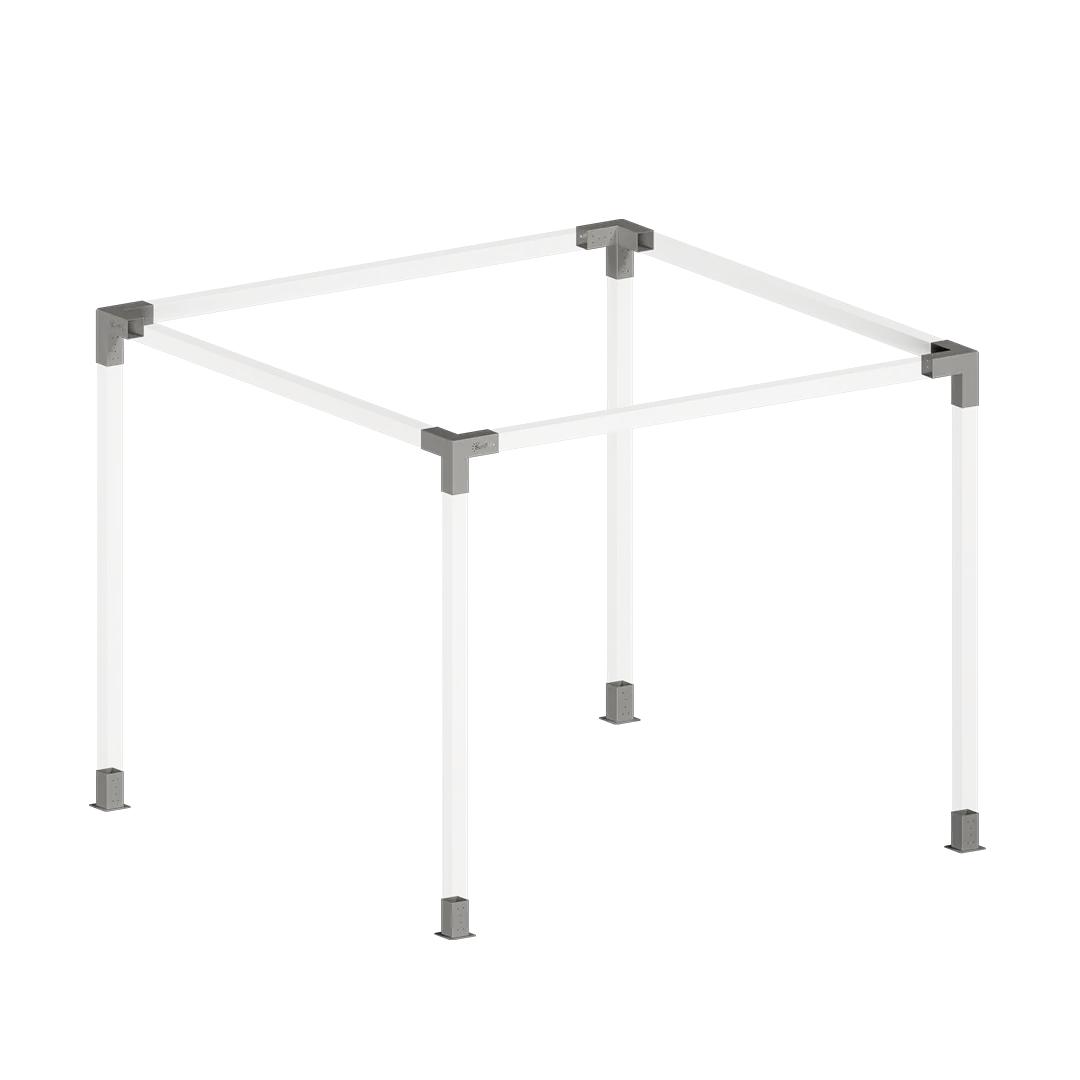

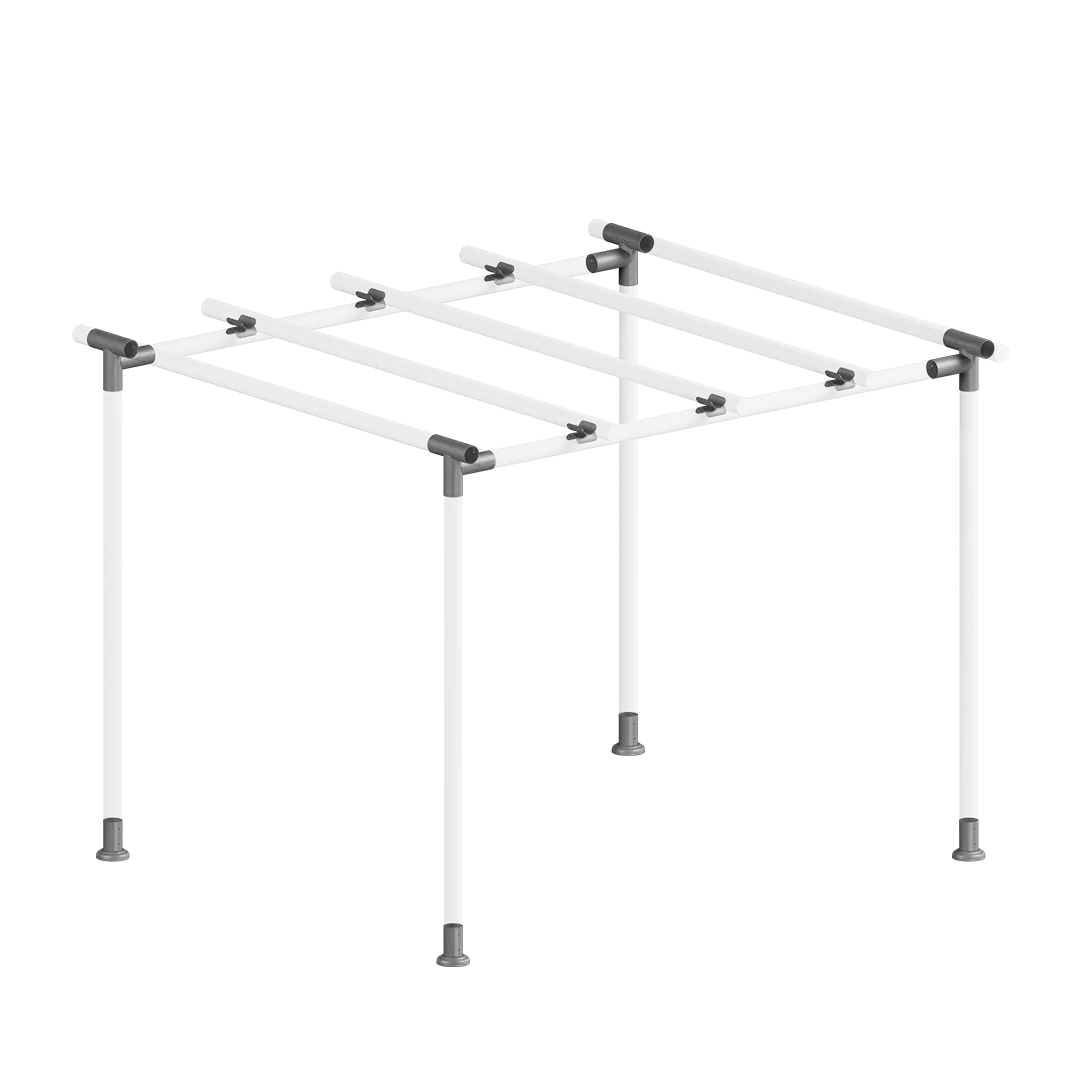

Strong Structure, Visual Quality, Easy Assembly

We produce Sunflex brackets, which are international products, using advanced technology and high-quality materials. As Sunflex, we are the leader in the production of highest quality pergola brackets.

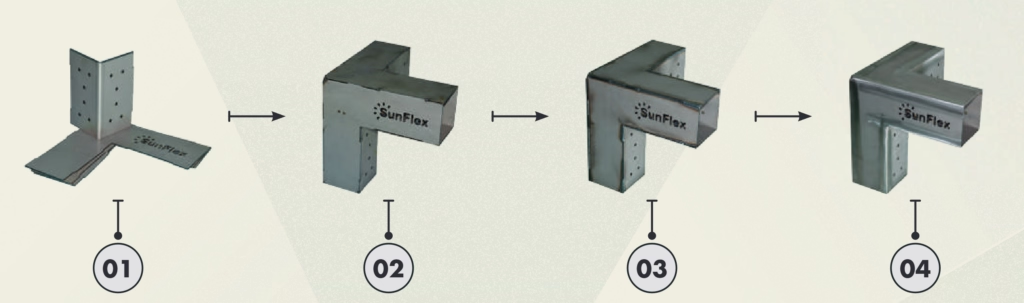

Laser Sheet Cutting

2.5 mm hrp sheet metal is precisely cut in laser cutting machines and bent in press brake machines.

Spot Welding

The product is spot welded in assembly fixtures and prepared for welding.

Welding

All joint surfaces are welded in robot laser welding machines, making the product a single piece and strong.

Grinding

The surfaces of the products with finished welding are precisely ground so that the joints are not visible.

The welding method of Sunflex brackets is the most important factor affecting its quality. Sunflex products do not have the intense spot internal welding seen in those made of galvanized sheet metal that prevents the timber from fitting comfortably into the slot, or the profile joint welding seen on the front face in galvanized box profiles. And compared to other production methods, a very solid single-piece product is obtained.

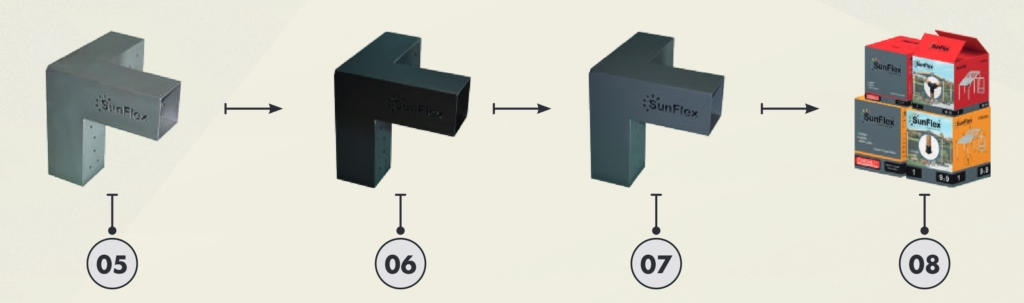

The cataphoresis process is the second most important factor affecting quality. It provides very high corrosion protection. You can see the application areas and method of the process below.

Sandblasting

Sandblasting is applied to the cut, drilled and welded surfaces of the products for better adhesion of cataphoresis and paint.

Cataphoresis Coating

Cataphoresis process is applied in a special facility.

Electrostatic Paint

After the parts are baked, electrostatic painting is performed.

Packaging

Screws and additional parts are added and carefully packaged in boxes.