Bracket Systems: Durability, Design and Usage Areas

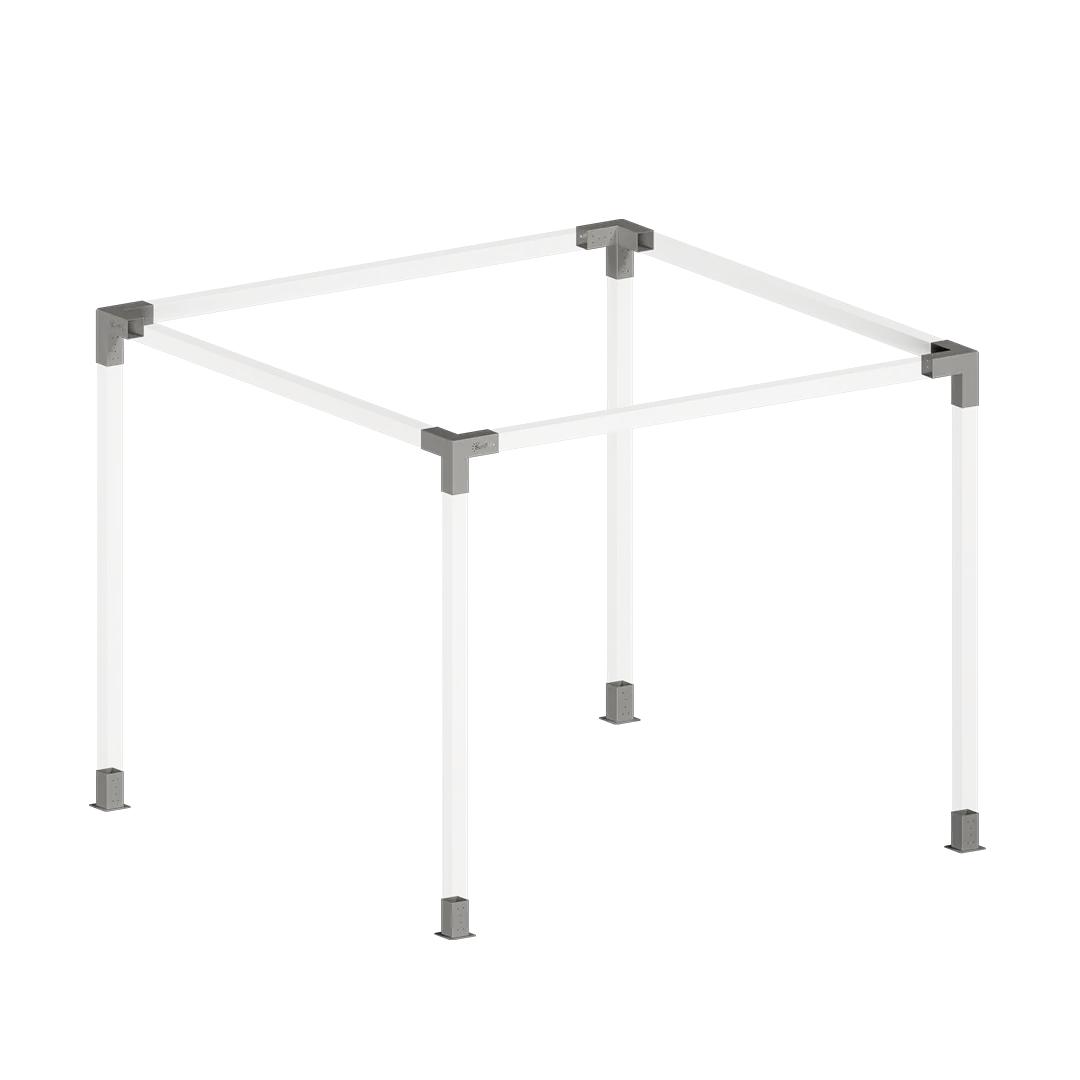

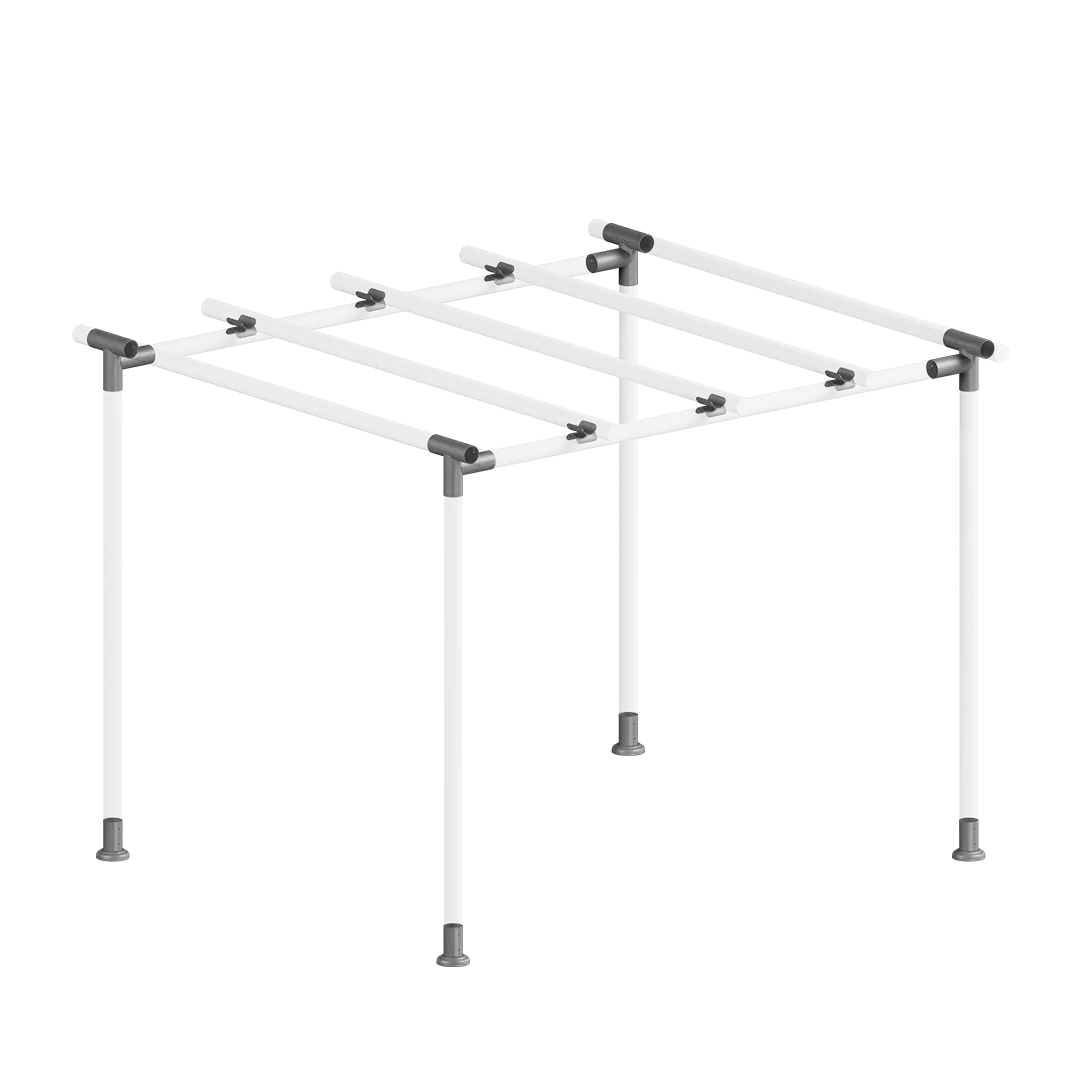

Bracket Systems Definition

Bracket systems are fasteners made of metal, plastic or composite materials produced to fix, support or strengthen two surfaces.

Special Advantages of Brackets

- High carrying capacity

- Easy installation

- Robust structure that can be used for many years

- Different size and design options

- Achieving aesthetic harmony with projects

In addition, thanks to modern production techniques, bracket systems now offer both durable and environmentally friendly solutions.

Where is it used?

Bracket systems are preferred in steel structure connections in the construction industry, in shelf and cabinet assembly in furniture production, in automotive part fixing and in electronic device assemblies. Especially furniture brackets are important for both visuality and safety.

Bracket Models

- L Bracket: Used in corner connections.

- T Bracket: Provides T-shaped connection.

- Adjustable Bracket: Can be adjusted for different angles.

- Decorative Brackets: Provides an aesthetic appearance in the interior.

- Special Production Brackets: Designed specifically for the project.

Materials Used

The most preferred materials include steel, stainless steel, aluminum and durable plastic. While steel models offer high strength, aluminum stands out with its lightness and plastic stands out with its economy.

Ease of Installation

New generation bracket systems can be installed quickly thanks to pre-drilled mounting holes and compatible fasteners. Some models are shipped disassembled and can be easily assembled in the field.

Use in the Industrial Sector

Thanks to their heavy load carrying capacity and vibration reduction features, brackets ensure the safe operation of machines in industry. Machine brackets extend the life of the equipment by minimizing vibration.

Decorative Use

Shelf brackets offer both aesthetic and functional solutions. Minimalist bracket models are preferred in modern spaces, while nostalgic designed brackets are preferred in classical decorations.

Price and Selection Criteria

Bracket prices vary depending on material quality, size, carrying capacity and design. Before purchasing, you should consider your intended use, the characteristics of the surface to be mounted and your aesthetic expectations.

As a result, bracket systems are indispensable for both industrial and decorative projects with their durability and versatility. You can achieve long-lasting results with your choices.